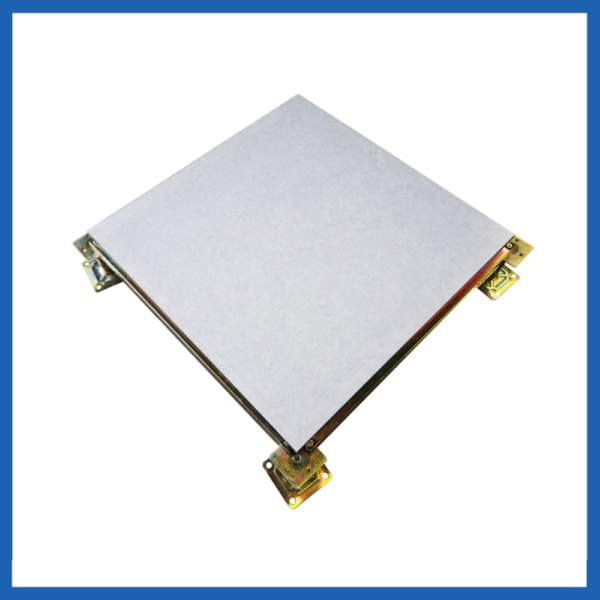

Characteristics of antistatic ceramic floor products:

1.Excellent heat resistance and strong decorative effect.

2.Wear resistance, corrosion resistance, flame retardancy, acid and alkali resistance, oil resistance and anti penetration.

3.Ceramic texture, never aging.

4.Non toxic, tasteless and radiation-free, it is a green environmental protection product.

5.The designs and varieties can be selected at will.

6.The dust generation is small, which can meet the requirements of high clean environment.

7.The construction is convenient and suitable for use in various new and old buildings.

8.System resistance: 1 × 106~1 × 109Ω

There are many kinds of anti-static floor, including: all steel anti-static floor, ceramic anti-static floor, calcium silicate anti-static floor, calcium sulfate anti-static floor, aluminum alloy anti-static floor, ventilation anti-static floor, PVC anti-static floor, ceramic anti-static tiles, etc. the scope of application is more extensive. Different types of anti-static floor are used in different anti-static places.

How to choose ceramic anti-static floor

More and more anti-static floor manufacturers in the market have mixed product quality. How should we choose ceramic anti-static floor?

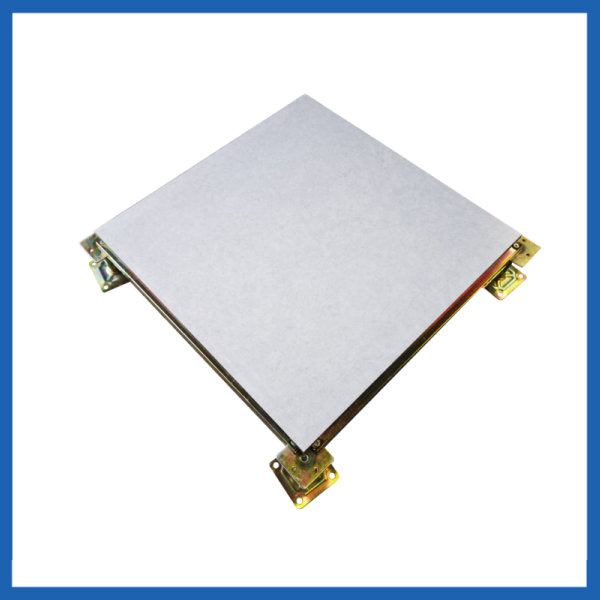

1、Look at the thickness of ceramic anti-static floor: Generally speaking, the thickness of ceramic anti-static floor is 40 or 45mm. If the floor is too thin, it will have a certain impact on the bearing capacity of the floor;

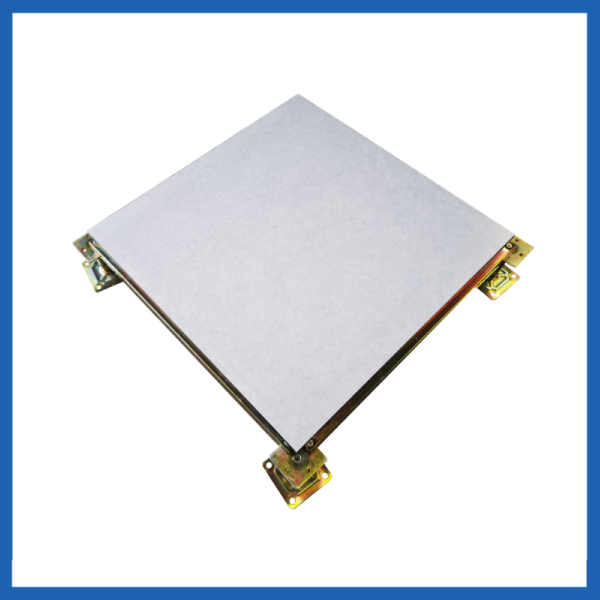

2、See the manufacturing process of ceramic anti-static floor: carefully observe whether the plastic spraying of steel shell is uniform, whether the floor surface is flat, and whether the internal filling is uniform;

3、Look at the wear-resistant layer of ceramic anti-static floor: the wear-resistant layer is made of melamine resin impregnated with surface paper added with wear-resistant material aluminum oxide, which is the key to determine the service life of ceramic anti-static floor. The wear-resistant layer endows the ceramic anti-static floor with important physical and chemical functions, such as wear resistance, scratch resistance, cigarette burning resistance, pollution resistance, corrosion resistance, moisture resistance, etc;

4、Look at the supports of the ceramic anti-static floor: the ceramic anti-static floor is much heavier than the ordinary anti-static floor, so it must be equipped with thick supports and beams to meet the design load requirements.

Ceramic anti-static floor, select the thickness

When we choose the ceramic anti-static floor, we should first look at the floor thickness. There are two floor specifications: 602*602*40mm and 602*602*45mm. Within the bearing range of the floor, the thicker the better. If the floor is too thin, it will affect the bearing capacity of the floor and our future use.

Second, the selection of ceramic anti-static floor looks at the anti-static performance

Anti static performance is a key function of ceramic anti-static floor, so we must choose anti-static ceramic tiles with anti-static performance. The anti-static index surface resistance value is 105-1010 Ω. There are few national standard anti-static ceramic colors, so there is not much room for selection. Recently, several new colors have been listed for everyone to choose from.

Three aspects of making ceramic anti-static floor

The manufacturing process of ceramic anti-static floor depends on the finished floor. First, check whether the plastic spraying of the steel shell is uniform, whether the surface is smooth and free of burrs, and then check whether the edges around the floor are firmly pasted. You can pull it with a little force by hand without obvious falling off.

Ceramic anti-static floor select four look floor accessories.

The support under the floor is very important and neglected by everyone, so we must see whether the support under the floor is thickened. Because the ceramic anti-static floor will weigh a lot more than the ordinary floor, so we must have a good support. Otherwise, if the time is long, it will also be prone to collapse. If possible, you can choose the noise elimination beam with leather.

It is widely used in electronic computer room, satellite ground station room, radio control room, TV transmitting station control room, microwave communication station room, program-controlled switching room, clean workshop, electronic instrument factory assembly workshop, confidential optical instrument manufacturing workshop, hospitals, schools and other places with static electricity prevention requirements, large and medium-sized computer rooms, communication rooms represented by switches, military and economic controlled by computers, National security, aviation, aerospace and transportation.